Do you know what a qualified hydraulic rotary joint goes through before leaving the factory?

In the world of heavy industry, robotics, and mobile machinery, components are often judged by their strength and resilience. Yet, for a device as central as a qualified hydraulic rotary joint, true quality lies not just in its robust exterior, but in a series of meticulous, often invisible, processes that it endures before ever reaching a customer. It’s a journey of precision, purification, and proof.

Many can manufacture a component that looks the part. But what separates a standard rotary union from a truly qualified hydraulic rotary joint capable of delivering millions of leak-free cycles under immense pressure? The answer is a fanatical commitment to a traceable, multi-stage quality control regimen.

For engineers designing a system, technicians maintaining it, and purchasing managers sourcing it, understanding this journey is not just an academic exercise. It’s the key to differentiating a component that will deliver reliable, leak-free performance for millions of cycles from one that could lead to costly downtime, safety hazards, and catastrophic system failure.

So, before leaving the factory, a qualified hydraulic rotary joint undergoes a rigorous series of steps to earn its final approval. Today, we pull back the curtain on such a process. We will walk you through the exact journey—from assembly to final packaging—that our qualified hydraulic rotary joint undergoes. As we explore each step, from ultra-high pressure cleaning to a grueling 30 MPa pressure test, ask yourself: Is this the level of scrutiny you demand for the critical components in your system?

Stage 1: The Foundation of Excellence – Meticulous and Traceable Assembly

Quality is not inspected into a product; it is built into it. This philosophy begins with the very first step: assembly.

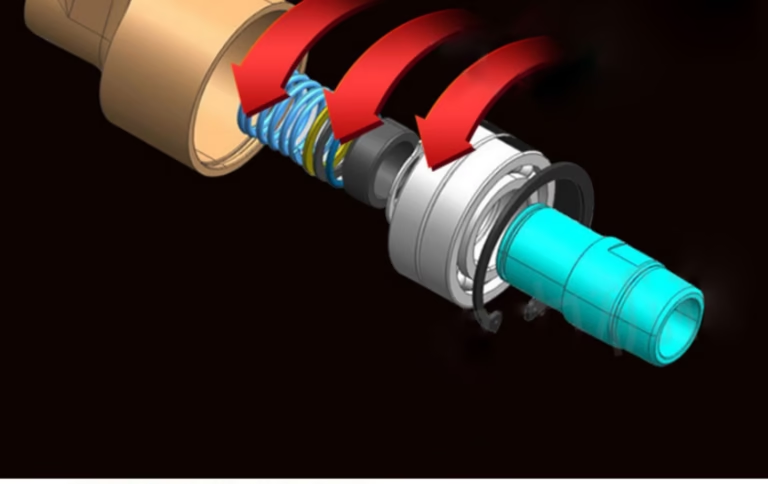

Unlike a simple set of parts bolted together, a hydraulic rotary joint brings precision components into a carefully orchestrated assembly, uniting them under strict control through a consistent, repeatable process.

Assembly by Certified Professionals

Each joint is assembled by a highly trained technician. These are not general laborers, but specialists who understand the nuances of seal installation and bearing alignment. They work from detailed Standard Operating Procedures (SOPs), ensuring that every single unit is built to the same high standard.

The Sanctity of Cleanliness

Before assembly even begins, every individual component—the housing, the shaft, the end caps—undergoes a rigorous purification process:

- Ultra-High Pressure Cleaning: This initial stage blasts away any residual machining fluids, metal shavings, or microscopic debris from the manufacturing process.

- Ultrasonic Cleaning: Technicians then submerge the components in a specialized bath and apply high-frequency sound waves. This process creates millions of microscopic bubbles that implode, generating a gentle but powerful scrubbing action that reaches into the smallest crevices and internal passageways, a place where brushes and sprays cannot go.

- Hot Air Drying: Finally, technicians dry the perfectly clean parts with filtered hot air in a controlled environment, preventing flash rusting and avoiding re-contamination from airborne particles.

Precision Assembly in Action

With pristine components, the technician begins the build. This includes the delicate installation of high-performance sealing rings, the press-fitting of bearings to exact depths using calibrated equipment, and the tightening of all bolts to a specific torque value with a calibrated torque wrench. This last step is crucial; improper or uneven torque can distort the housing, leading to premature seal failure.

Our team documents every one of these steps in the factory files, linking them to the product’s serial number. This creates an unbroken chain of accountability and traceability for every single unit.

Stage 2: The Crucible – The 30 MPa Hydraulic Pressure Test

Once assembled, the rotary joint faces its first and most formidable trial: the pressure test. This is not a spot check; it is a mandatory gateway that every single unit must pass. For a high-pressure rotary union designed for demanding applications, the test must be equally demanding.

Technicians conduct the test using hydraulic oil, pressurizing the system to 30 MPa (approximately 4,350 PSI). This pressure level reflects the severe conditions encountered in heavy construction equipment, industrial presses, and high-performance manufacturing systems. During this intense test, we focus on two critical indicators of quality:

1. Shell Integrity: The Search for Micro-Defects

- The Test: While held at a steady 30 MPa, the entire exterior surface of the rotary joint is meticulously inspected by a quality control engineer.

- The Standard: The judgment standard is absolute: zero oil leakage. The tiniest bead of oil appearing on the surface of the housing is cause for immediate rejection.

- Why It Matters: This test is designed to expose hidden material defects like porosity or “sand holes”—microscopic voids within the metal casting or billet that are invisible to the naked eye. Under immense pressure, these weak points can allow fluid to seep through the housing wall. A joint that passes this test has proven its material soundness and its ability to contain extreme pressure without failure, ensuring both operational reliability and worksite safety.

2. Sealing Performance: The Pressure Drop Analysis

- The Test: After technicians complete the visual inspection, they isolate the joint from the pressure source and monitor the internal pressure for a set period using a high-precision digital pressure transducer.

- The Standard: The internal pressure must remain stable, with any drop falling within a very narrow, pre-defined tolerance (e.g., less than 0.5% over 5 minutes).

- Why It Matters: This test directly evaluates the performance of the internal seals—the very heart of the rotary joint. A significant pressure drop indicates a microscopic leak past the main seals between the rotating shaft and the stationary housing. When the joint passes this test, it proves that the seals fit perfectly, the sealing surfaces meet flawless finishing standards, and the joint delivers the leak-free performance needed for efficient and clean operation.

If a product fails either test, our quality team immediately sends it to a dedicated analysis and repair station. There, technicians disassemble the unit, identify the root cause of the failure, and take corrective action. It must then pass the entire pressure test sequence again from the beginning. No exceptions.

Stage 3: The Invisible Standard – The Internal Cleanliness Test

A joint can be structurally sound and leak-free, but still be a liability if it is not internally clean. Contamination is the invisible enemy of any hydraulic system. Microscopic particles left over from manufacturing or assembly can travel downstream, damaging expensive pumps, sticking precision valves, and clogging filters, leading to system-wide failure.

To prevent this, every rotary joint must pass a stringent internal cleanliness test.

The Standard: The fluid within the joint must achieve NAS 1638 Class 7 cleanliness.

Why It Matters: The National Aerospace Standard (NAS) 1638 is a globally recognized system for classifying particulate contamination in hydraulic fluids. It defines specific limits on the number of particles of different sizes allowed in a 100ml fluid sample.

- NAS 7 is a highly demanding standard of cleanliness, typically required for sensitive hydraulic and servo-valve systems.

- Achieving this level is a direct result of the multi-stage cleaning process performed before assembly. It is a guarantee that the component you install will not introduce harmful contaminants into your pristine hydraulic circuit. For an engineer designing a complex system, this is a critical assurance of system-level reliability.

Stage 4: The Protective Shield – Finishing and Final Inspection

With its performance and purity confirmed, the qualified joint moves to the finishing line. This process is about providing long-term protection and ensuring final usability.

Surface Preparation

The exterior is once again cleaned to ensure perfect adhesion for the coating.

Primer Spraying

Next, our technicians apply a layer of high-quality primer, which creates a strong bonding foundation and serves as the first protective barrier against corrosion, ensuring the rotary joint’s durability in harsh environments.

Topcoat Spraying

Afterward, our team applies a durable, industrial-grade topcoat that serves as the primary defense against moisture, chemicals, and physical abrasion, significantly enhancing the rotary joint’s protection and lifespan in demanding operating environments.

Air Drying

Workers move the painted units to a controlled drying area. The coating cures fully there. This process achieves maximum hardness and durability.

After curing, the product is not yet finished. It undergoes another round of inspection:

- Coating Thickness & Adhesion Tests: The paint thickness is measured with a digital gauge to ensure it meets the specification for effective protection. An adhesion test (like a cross-hatch test) is performed to guarantee the paint will not chip or flake off during handling or operation.

- Final Port Inspection: All oil ports are meticulously inspected to ensure no paint or debris has entered. Technicians remove the temporary test plugs. They install new, clean shipping plugs. These seal the unit against contamination during transit.

The Final Verdict: The Certificate of Conformity

Only after a product has successfully passed every single one of these stages—from assembly and pressure testing to cleanliness and finishing—will the Quality Inspection Department issue its final approval: the Certificate of Conformity.

This document, which accompanies the product, is more than a piece of paper. It is a formal declaration. The specific serialized rotary joint in the box passed all quality control tests. It has endured and conquered the entire gauntlet. It is our promise to you that it meets every standard of performance, reliability, and safety.

Finally, our packaging team carefully wraps the certified product in custom-fit protective materials and seals it for shipment, guaranteeing that the quality we built and inspected is exactly the quality you receive.

| Test Phase | Purpose | Key Metrics & Methods | Why It Matters for You |

|---|---|---|---|

| Dimensional & Geometric Inspection | To ensure all parts meet the exact design specifications. | CMM (Coordinate Measuring Machine), digital calipers, micrometers. Checks for concentricity, parallelism, and tolerances. | Guarantees interchangeability of parts and proper fit, which is fundamental for performance. |

| Material Hardness & Roughness Test | To verify that surface treatments meet durability requirements. | Rockwell hardness tester, surface profilometer. | Ensures the joint will resist wear and that the sealing surfaces are optimized for long seal life. |

| Static Proof Pressure Test | To confirm the structural integrity of the joint's housing and seals under extreme static load. | The joint is filled with hydraulic fluid and pressurized to 1.5x to 2.0x its maximum rated working pressure and held for a set period (e.g., 5-10 minutes). | This is your safety guarantee. It proves the joint won't burst or leak under unexpected pressure spikes. |

| Low-Pressure Air Leakage Test | To detect microscopic leaks that might not be visible with hydraulic fluid. | The joint is pressurized with low-pressure air (e.g., 0.6-0.8 MPa) and submerged in water or monitored by a pressure decay sensor. | Ensures a perfect seal, which is critical for preventing fluid loss and environmental contamination over time. |

| Dynamic Rotational Test | To simulate real-world operation and check for leaks or performance issues while rotating. | The joint is mounted on a test rig, pressurized to its rated working pressure, and rotated at a specified speed. | This is the ultimate "real-world" check. It confirms the rotary joint seal technology works not just when static, but in motion, which is its primary function. |

| Rotational Torque Test | To measure the friction or "drag" of the rotary joint. | A torque sensor measures the force required to rotate the shaft at various pressures. | For engineers, this data is crucial for motor sizing and system efficiency calculations. Low torque means less wasted energy. |

| Life Cycle & Endurance Testing (Batch) | To validate the design's long-term reliability and lifespan. | A sample from a production batch is run continuously for hundreds of thousands or even millions of cycles, often under accelerated conditions. | This is a key concern for purchasing. It provides data-driven confidence in the joint's TCO (Total Cost of Ownership) and helps in rotary joint failure analysis. |

So, Would You Choose This Level of Quality?

Now, we return to the initial question.

When you choose a hydraulic rotary joint, you are making a decision that impacts system efficiency, maintenance schedules, operational safety, and your bottom line.

- For the Engineer: A product backed by this process means predictable performance you can design around with confidence. The 30 MPa proof test removes variables in your hydraulic system. The NAS 7 cleanliness rating safeguards your system’s integrity. Together, they ensure reliable and clean operation.

- For the Technician: This means a reliable component that installs easily and works correctly from day one. It means fewer emergency calls, less time spent troubleshooting leaks, and longer intervals between maintenance.

- For the Purchasing Manager: This process is your ultimate assurance of value and risk mitigation. It demonstrates a supplier’s commitment to quality that goes far beyond surface-level specifications. A qualified hydraulic rotary joint helps lower the Total Cost of Ownership (TCO). It prevents costly downtime and system failures. This protection saves your company significant expenses.

In a competitive market, it may be tempting to source a component that simply “meets the specs” on paper. But as this deep dive shows, the true measure of a product lies in the rigor of the process it survives. When reliability is non-negotiable, the choice becomes clear.

If you are sourcing hydraulic rotary joints for industrial applications, always request test certificates, serial numbers, and quality compliance documentation to verify that your component is truly qualified.