How to maintain your hydraulic rotary joints for Optimal Performance: The Expert Guide

In the world of industrial machinery, hydraulic rotary joints are unsung heroes. These critical components are responsible for transferring pressurized hydraulic fluid from a stationary source to a rotating machine part, enabling the smooth and continuous operation of heavy-duty equipment. When a hydraulic rotary joint fails, it can lead to costly downtime, production losses, and potential safety hazards.

To help you protect your investment and maintain peak performance, we’ve created this expert guide on how to maintain your hydraulic rotary joints properly. Whether you’re an engineer, a technician, or a procurement manager, this comprehensive guide will provide you with the knowledge and actionable steps needed to extend the life of your equipment and prevent unexpected failures.

Introduction of Hydraulic Rotary Joints

Hydraulic rotary joints are integral components in industrial systems that allow the transfer of fluids or gases between stationary and rotating parts. These components are widely used in various applications such as manufacturing, construction, and energy production. Ensuring that these rotary joints are properly maintained is critical to maximizing their longevity and preventing costly failures.

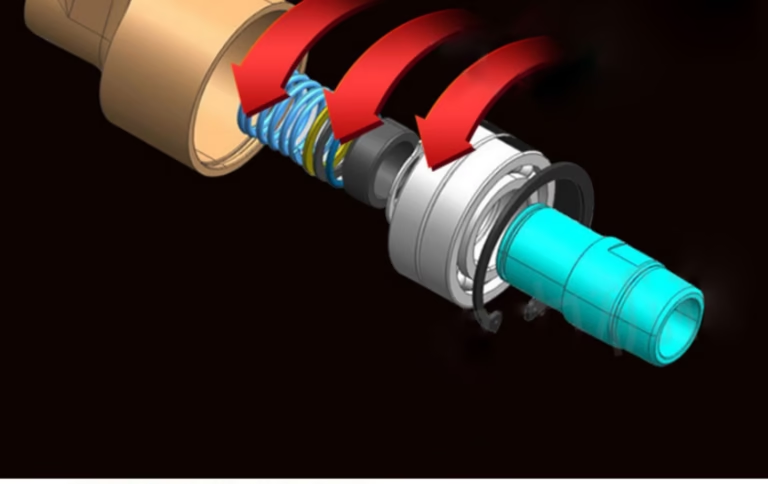

As a self-balancing element, the hydraulic rotary joint can transfer pressurized oil or other fluids to the hydraulic rotary cylinder, so that the piston of the equipment moves left and right, thereby achieving radial loosening of the power chuck. During the return stroke, the hydraulic rotary joint benefits from the pressure oil to release pressure, and resets through the action of the spring to achieve chuck clamping. The rotary seal part of the hydraulic rotary joint is installed on the core shaft of the equipment, and its main function is to form two independent sealing spaces to isolate the oil inlet chamber.

In this article, we will explore the essential Hydraulic rotary joint maintenance guide and best practices for maintaining Hydraulic rotary joint maintenance guide, focusing on preventing common failures, reducing downtime, and enhancing performance. We will also dive into key aspects like cleaning, lubrication, sealing, and monitoring to extend the life of hydraulic rotary joints. Hydraulic rotary joints

Hydraulic rotary joints

Understanding Hydraulic Rotary Joints and Their Role in Industrial Systems

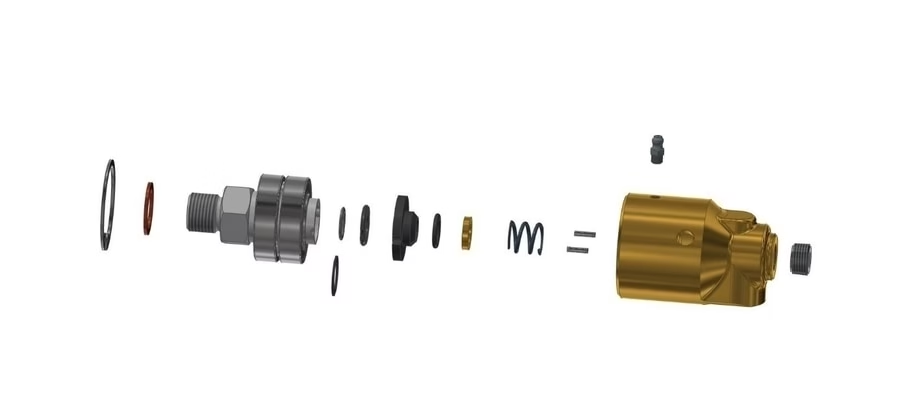

Hydraulic rotary joints, also known as rotary unions or fluid swivels, are designed to transfer hydraulic fluids, steam, or other media to rotating equipment. They serve as the crucial interface that enables the transfer of hydraulic fluid between stationary supply lines and rotating machinery components. These precision components consist of carefully engineered seals, bearings, and flow passages that must work in harmony to maintain system integrity while allowing continuous rotation. These joints provide a continuous flow of fluid or gas to a rotating part, such as a drum or shaft, while maintaining a seal to prevent leaks.

Before we dive into maintenance, it’s crucial to understand what a hydraulic rotary joint does and the forces it withstands. A hydraulic rotary joint, also known as a hydraulic swivel joint or hydraulic rotary union, is a sealed device that allows for the rotation of machinery while maintaining a high-pressure fluid connection. They are essential in applications such as:

- Excavators and Cranes: For the continuous rotation of the cab and arm.

- Robotics: Providing hydraulic power to robotic arms and grippers.

- Machine Tools: Supplying coolant or hydraulic fluid to spindles and turrets.

- Agricultural Machinery: Enabling the operation of rotating components on harvesters and tractors.

The operational demands placed on these components are significant – they must withstand high pressures, varying temperatures, and continuous rotational stress while preventing leaks. Without properly functioning rotary joints, many automated systems would be impossible to operate efficiently, making their maintenance a critical aspect of overall system reliability.

Hydraulic rotary joints maintenance guide

1. Regular Inspection and Monitoring

One of the most critical aspects of maintaining hydraulic rotary joints is consistent and thorough inspection. Regular checks help identify any issues before they escalate into significant problems.

1.1 Establishing Inspection Protocols

The foundation of effective rotary joint maintenance is systematic inspection. Regular visual examinations should focus on:

🚨 Fluid Leakage

Watch for signs of fluid leakage or seepage around seals.

🔊 Unusual Noise or Vibration

Monitor for abnormal sounds or vibrations during operation.

♨️ Excessive Heat

Check for unusual heat generation at the joint interface.

🔄 Abnormal Resistance

Feel for irregular resistance during rotation.

🔩 Mounting & Connections

Inspect the condition of the mounting hardware and all connections.

1.2 Routine Inspection Tips for Hydraulic Rotary Joints

💧 Check for Leaks

Inspect connection points for hydraulic fluid leaks.

Leaks may indicate worn seals or component failure.

🛑 Inspect Seals

Seals can degrade due to pressure, temperature, or contamination.

Look for cracks, wear, or deformation.

👁️ Visual Inspection

Ensure no external debris or contaminants are present.

Keep the joint clean to maintain optimal performance.

Developing a consistent inspection schedule – daily quick checks, weekly detailed examinations, and monthly comprehensive inspections – helps identify developing issues before they lead to catastrophic failures. Even seemingly minor changes in performance can indicate the early stages of potential problems.

2. Lubrication and Greasing

Many hydraulic rotary joints incorporate separate lubrication systems for bearings and seals that are distinct from the main hydraulic fluid path. Proper lubrication is essential to reduce friction, prevent wear, and ensure smooth operation of hydraulic rotary joints. Using the right lubricant, as per the manufacturer’s specifications, will reduce the chances of overheating and corrosion.

Since the machine has not been used for a long time, it will directly cause scaling and rust inside the hydraulic rotary joint. Please note that if it is used again, it will be stuck or fall off. Please regularly fill oil with the oil filling device to ensure the reliability of the hydraulic rotary joint bearing operation.

Effective Lubrication Management for Rotary Unions

✅ Follow Manufacturer Guidelines

Use the correct type of grease or oil as recommended.

🔄 Lubricate Regularly

Maintain lubrication at specified intervals to prevent excessive friction and failure.

🛢️ Use High-Quality Lubricants

Ensure lubricant compatibility with system fluids for optimal performance.

🔧 Self-Lubricating? Still, Check!

Even self-lubricating rotary unions need periodic checks on lubricant conditions and levels.

⭐ Proper lubrication greatly extends the life of rotary unions by reducing friction and wear.

3. Maintaining Fluid Quality and Filtration

The quality of the hydraulic fluid used in the system directly impacts the performance of the rotary joints. Contaminants, such as dirt, water, and metal particles, can cause premature wear and failure of the seals and internal components. Keep the inside of the hydraulic rotary joint drum and the pipe clean. Special attention should be paid to new equipment, and filters should be added if necessary to avoid abnormal wear caused by foreign matter on the hydraulic rotary joint.

Hydraulic System Maintenance Tips

🧹 Use Filters

Install high-quality filters to block contaminants from entering the system.

🔄 Regular Fluid Changes

Replace hydraulic fluid at recommended intervals to prevent contamination buildup.

⚙️ Check Fluid Levels

Keep fluid levels within manufacturer guidelines to avoid air entry, pump cavitation, and potential system failure.

4. Temperature and Pressure Control

Hydraulic rotary joints operate optimally within specific temperature and pressure ranges. Maintaining these parameters is crucial to ensuring their longevity. The hydraulic rotary joint that circulates the hot medium should be heated gradually to avoid sudden changes in temperature. Check the wear and thickness change of the sealing surface of the hydraulic rotary joint (normal wear is 50×1773 10mm). Observe the friction track of the sealing surface to see if there are problems such as three-point discontinuity or scratches. If there are any of the above conditions, replace them immediately.

Pressure & Temperature Management Tips

📊 Monitor Pressure & Temperature

Use monitoring devices to maintain safe operating ranges.

❄️🔥 Avoid Temperature Extremes

Extreme heat or cold can accelerate seal wear and reduce joint lifespan.

🛡️ Install Pressure Relief Valves

Prevent system pressure from exceeding safe limits to avoid internal damage.

4.1 Pressure Management

Operating rotary joints at incorrect pressures is a common cause of premature failure.

Effective pressure management includes

✅ Verify Operating Pressure

Ensure pressures stay within the manufacturer’s specifications.

🛡️ Install Pressure Relief Systems

Prevent dangerous pressure spikes that can damage the system.

📈 Monitor Pressure Fluctuations

Watch for irregular changes that may signal potential issues.

🔄 Understand Pressure & Sealing

Know how pressure impacts sealing effectiveness for safe, reliable operation.

Most pneumatic systems operate at around 100 PSI, while hydraulic systems can range up to 3500 PSI. This significant difference highlights the importance of using components rated for the specific pressure range of your application.

4.2 Temperature Monitoring

Temperature affects the seal temperature.e Management involves

✅ Monitor Operating Temperatures

Track temperatures during normal operation.

🚨 Identify Abnormal Heat

Detect unusual heat increases that may signal friction issues.

💧 Control Fluid Temperatures

Keep hydraulic fluid within specified limits.

🔥 Protect from External Heat

Shield rotary joints from external heat sources when possible.

5. Proper Installation and Alignment

Installation & Alignment Best Practices

✅ Proper Installation

Always follow the manufacturer’s mounting guidelines to ensure correct setup.

🎯 Accurate Alignment

Ensure rotating and stationary parts are properly aligned to prevent uneven wear.

📉 Monitor Vibration

Watch for excessive vibration, which may signal misalignment or mounting issues.

⚠️ Misalignment and vibration can damage bearings, loosen hardware, and rapidly wear seals, leading to system failure.

Vibration Monitoring Best Practices

✅ Establish Baseline

Record normal vibration levels for future comparison.

🔄 Periodic Checks

Regularly monitor for vibration changes that may signal issues.

🎯 Correct Alignment

Fix alignment problems that can cause excessive vibration.

🛠️ Ensure Proper Mounting

Reduce transmitted vibration with secure, correct mounting.

🔍 Predictive Maintenance

Use vibration analysis to detect problems early and prevent failure.

6. Seal Maintenance and Replacement

Seals are crucial for maintaining pressure and preventing leaks in hydraulic rotary joints. Over time, seals wear down, become brittle, or break, causing fluid leaks and system malfunctions.

Seal Maintenance Tips for Hydraulic Rotary Joints

🔍 Regular Seal Inspections

Check seals frequently for wear, damage, or corrosion.

⚙️ Replace Damaged Seals

Promptly replace worn or damaged seals to prevent leaks and pressure loss.

🏷️ Use OEM Seals

Always use original manufacturer seals for proper fit and reliable performance.

7. System Pressure Balancing

Balancing the pressure within the hydraulic system is crucial for preventing damage to hydraulic rotary joints. Pressure imbalances can cause stress on seals and internal components.

Hydraulic Pressure Safety Tips

⚖️ Hydraulic Pressure Regulation

Keep system pressure within safe limits to prevent joint failure.

🛡️ Pressure Relief Valves

Install valves that activate when pressure exceeds safe levels, protecting the system from damage.

8. Training and Documentation

Training personnel on the importance of hydraulic rotary joint maintenance is critical for ensuring proper care. Additionally, maintaining comprehensive records of maintenance activities can help identify recurring issues and track the system’s health.

Operator Training & Record Keeping

👷 Operator Training

Equip operators and maintenance staff to spot early failure signs and perform proper maintenance.

🗂️ Keep Detailed Records

Maintain logs of inspections, repairs, and replacements for troubleshooting and system optimization.

9. Routine Performance Testing

Conducting performance tests can help detect inefficiencies or signs of wear that might not be visible during routine inspections.

Key Testing Methods for Hydraulic Rotary Joints

💧 Flow Testing

Verify flow rate matches specifications.

⚖️ Pressure Testing

Ensure the joint handles the required operational pressure without failure.

📊 Vibration Analysis

Monitor vibrations to detect misalignment or other issues early.

10. Maintenance Points for Compact Swivel Joint

To ensure long-term performance, safety, and durability of your compact swivel joint, follow these essential maintenance practices:

Keep the System Clean

Always keep the rotary joint drum and internal pipe surfaces clean during routine maintenance. Foreign particles such as dust, debris, or residues can cause abnormal wear, clogging, or internal scoring that leads to premature failure.

Install Filtration Devices

For newly installed equipment, it’s highly recommended to incorporate inline filters or strainers. These components help block contaminants from entering the rotary joint and the connected pipeline, significantly reducing the risk of internal damage.

Avoid Prolonged Downtime Without Use

If the equipment remains unused for an extended period, moisture and fluid residues may lead to internal rusting, scaling, or clogging. This can cause jamming, leakage, or increased torque when the system is reactivated. Regular operation or protective flushing can prevent these issues.

Perform Regular Lubrication

If your rotary joint includes an oiling or grease port, follow the manufacturer’s recommended lubrication schedule. Consistent oiling ensures smooth bearing operation, reduces friction, and helps prevent overheating or seizing during high-speed rotation.

Gradual Temperature Ramp-Up

When working with hot media such as steam, oil, or thermal fluids, always increase the system temperature gradually. Sudden thermal shock can cause seal deformation, metal fatigue, or even cracking of internal components.

Inspect the Sealing Surface Frequently

Monitor the sealing surface for signs of wear, reduced thickness, unusual friction marks, or scoring. Abnormalities in the seal face can lead to leaks or complete failure. Replace worn seals promptly to maintain pressure integrity and system efficiency.

Handle with Caution

Rotary joints are precision components. During installation, maintenance, or relocation, avoid any physical impacts. Dropping or knocking the unit may result in internal misalignment, cracks, or performance degradation.

Prevent Foreign Material Intrusion

Never allow foreign materials—such as metal shavings, sand, or liquids—to enter the rotary joint. These contaminants can cause seal abrasion, unbalanced rotation, or even catastrophic failure during operation. Always cover open ports during storage or downtime.

By implementing these proactive maintenance steps, you’ll extend the service life of your compact swivel joint and ensure optimal performance in your application, whether in hydraulic systems, robotics, packaging machinery, or rotating automation tools.

Addressing Common Failure Modes

1. Seal Deterioration and Failure

Seals are perhaps the most vulnerable components in hydraulic rotary joints.

Common Causes of Seal Failure & Prevention

❌ Causes of Seal Failure

Natural aging and wear

Chemical incompatibility with fluids

Excessive temperature exposure

Operating beyond pressure limits

Contamination damage

🛡️ Prevention Strategies

Choose the right seal materials for your application

Maintain fluid cleanliness

Monitor operating temperatures

Replace seals before critical wear

2. Bearing Issues

Bearings support the rotational elements while maintaining proper alignment.

Common Bearing Issues & Prevention

⚠️ Common Issues

Inadequate lubrication → Excessive friction

Contamination → Accelerated wear

Misalignment → Uneven loading

Excessive loads beyond specs

Vibration damage over time

🛠️ Prevention Tips

Regular bearing inspection

Proper lubrication

Verify correct alignment

Monitor early signs: noise & heat

3. Fluid-Related Problems

Hydraulic Fluid Quality & Its Impact

⚠️ Issues from Poor Fluid Quality

Contamination → Accelerated seal & surface wear

Wrong viscosity → Poor flow & lubrication

Fluid degradation → Reduced lubrication effectiveness

Water or air presence → Erratic operation

Chemical breakdown → Seal damage

🛡️ Prevention Tips

Regular fluid analysis

Use proper filtration

Schedule a timely fluid replacement

Ensure fluid compatibility with seals

Installation and System Design Considerations

1. Proper Mounting and Alignment

Installation Tips for Rotary Joint Longevity

✅ Follow the manufacturer’s Torque Specs

Ensure mounting hardware is tightened correctly.

🎯 Verify Alignment

Align the stationary and rotating parts precisely.

↔️ Minimize Side Loading

Avoid lateral forces on the rotary joint.

🔧 Provide Adequate Support

Support both the joint and connected components.

⚠️ Address Misalignment Promptly

Fix alignment issues immediately to prevent damage.

Many rotary joint failures can be traced back to improper initial installation. Taking time to ensure correct mounting and alignment pays dividends through extended service life.

2. Managing Rotational Requirements

Best Practices for Flexible Supply Lines to Rotary Joints

➰ Provide Service Loops

Allow enough slack to accommodate rotation.

🛠️ Proper Line Support

Prevent stress on connections with secure supports.

✅ Use Rated Flexible Hoses

Choose hoses suitable for your specific application.

🛡️ Protect Supply Lines

Guard against mechanical damage.

🔄 Manage Rotation

Consider rotation limits or continuous rotation needs.

For applications requiring limited rotation (less than 360 degrees), a flexible hose with a service loop may be sufficient. For continuous or unlimited rotation, specialized rotary unions are essential.

3. Environmental Protection

Environmental Protection for Rotary Joints

🛡️ Shield from Dirt, Dust & Moisture

Keep contaminants away to ensure smooth operation.

♨️ Provide Thermal Protection

Guard against extreme temperatures.

⚠️ Prevent Corrosive Exposure

Avoid contact with harmful chemicals.

🚧 Protect from Impact & Damage

Safeguard joints from mechanical harm.

🍂 Address Seasonal Variations

Adjust maintenance for changing operating conditions.

Simple protective measures often deliver substantial improvements in service life and reliability, particularly in harsh industrial environments.

Developing a Comprehensive Maintenance Schedule

1 . Daily Checks

Quick Checks for Rotary Joint SOP

🔎 Visual Inspection

Look for leaks or unusual conditions.

👂 Listen Carefully

Detect abnormal sounds during operation.

📊 Monitor Parameters

Check pressure and temperature regularly.

🔄 Verify Rotation

Ensure smooth and normal rotation behavior.

These daily checks require minimal time investment but provide valuable early warning of developing issues.

2. Weekly Maintenance Tasks

🔍 Inspect Seals

Check sealing areas for signs of weeping or leaks.

🧼 Clean Surfaces

Clean external parts and inspection ports.

🔧 Verify Hardware

Ensure mounting bolts and hardware are tight.

📈 Record Data

Log operating parameters for trend analysis.

Weekly maintenance creates opportunities to catch developing issues before they progress to serious problems.

3 . Monthly Procedures

Comprehensive Rotary Joint Evaluation

✅ Full Component Inspection

Examine all accessible parts thoroughly.

🛢️ Lubrication Service

Perform lubrication as per the manufacturer’s guidelines.

💧 Fluid Condition Check

Verify the cleanliness and quality of hydraulic fluid.

⚠️ Check Alignment & Wear

Identify misalignment or excessive wear early.

Monthly maintenance provides deeper insights into component health and enables planning for more extensive maintenance actions if needed.

4 . Annual Overhaul Considerations

Major Maintenance During Planned Shutdowns

🔧 Complete Disassembly & Inspection

A thorough check of all parts, where possible.

🔄 Replace Worn Components

Follow service schedules for part replacement.

📏 Verify Dimensions & Tolerances

Ensure critical measurements are within specs.

🧪 Controlled Testing

Test under controlled conditions before restart.

📋 Document Findings

Keep detailed records for future reference.

Annual maintenance activities may require manufacturer involvement or specially trained personnel, particularly for high-performance or critical applications.

Advanced Maintenance Techniques of

1 . Implementing Predictive Maintenance of

Condition-Based Maintenance Techniques

📈 Vibration Analysis

Detect bearing degradation early.

🌡️ Infrared Thermography

Identify developing heat-related issues.

🛢️ Oil Analysis

Monitor contamination and wear particles.

📊 Performance Trending

Track gradual equipment degradation.

🎧 Acoustic Monitoring

Early detection of internal faults via sound.

These techniques allow maintenance to be performed based on actual component conditions rather than arbitrary schedules, potentially extending service intervals while maintaining reliability.

2 . Specialized Tools and Equipment for Hydraulic Rotary Joint Maintenance Guide

Specialized Tools for Effective Maintenance

⚖️ Pressure Testing Equipment

Verify seal integrity reliably.

🎯 Alignment Tools

Ensure precise installation.

🔧 Torque Wrenches

Achieve accurate fastener tightening.

💧 Flow Meters

Check performance flow characteristics.

🌡️ Temperature Devices

Monitor thermal conditions precisely.

Investing in appropriate tools ensures maintenance tasks are performed correctly and consistently, reducing the risk of errors that could lead to premature component failure.

Special Considerations for High-Demand Applications

1 . High-Pressure Systems

Maintenance Tips for High-Pressure Applications

⏱️ Frequent Inspections

Increase inspection intervals for safety.

🛡️ Enhanced Filtration

Use superior filtration systems.

🔄 Pressure Cycling Awareness

Consider the effects of pressure fluctuations.

✅ Safety Margins

Select components with appropriate safety factors.

📊 Enhanced Monitoring

Closely track operating parameters.

High-pressure applications place exceptional demands on sealing systems and structural components, necessitating more rigorous maintenance approaches.

2 . Continuous Operation Applications

Maintenance Strategies for Continuous Operation Systems

📡 Design for Online Monitoring

Enable real-time system health tracking.

🔁 Implement Redundant Systems

Ensure backup components, where possible.

⚡ Quick-Change Procedures

Develop fast replacement methods for critical parts.

📈 Enhanced Predictive Maintenance

Maximize the effectiveness of planned upkeep.

🎓 Specialized Training

Equip maintenance staff with targeted skills.

Planning for maintenance in continuous operations requires balancing production requirements with component longevity considerations.

Troubleshooting Common Issues

1 . Identifying and Resolving Leaks

Common Rotary Joint Leak Issues & Solutions

🔍 Leak Source Tracking

Identify if from a static seal, a dynamic seal, or a housing crack.

⏳ Leakage Timing

Check if the leak is continuous or operation-specific.

🔧 Connection Tightness

Verify that all fittings and mounting hardware are secure.

🛡️ Seal Condition

Inspect for damage or contamination.

📋 Operating Conditions

Ensure parameters are within specs.

⚠️ Prompt Action

Prevent fluid loss, contamination, and safety risks by timely fixing leaks.

2 . Addressing Excessive Resistance

Troubleshooting Rotary Joint Resistance to Rotation

🛢️ Lubrication Check

Ensure bearings and seals are properly lubricated.

🎯 Alignment Verification

Confirm the correct alignment of connected components.

🧹 Debris Inspection

Look for contamination affecting movement.

🔧 Installation Review

Check for binding or side-loading issues.

📊 Operating Pressure

Verify pressures are within specifications.

Excessive resistance not only affects system performance but can also lead to accelerated wear and eventual component failure if not addressed.

Conclusion

Hydraulic rotary joints play a crucial role in ensuring the smooth operation of industrial systems. By following the Hydraulic rotary joint maintenance guide in this article, such as regular inspections, proper lubrication, seal maintenance, and pressure and temperature control, you can significantly extend the lifespan of these components and prevent costly failures.

Adhering to a structured maintenance routine not only ensures the efficiency of the system but also reduces unexpected downtime, enhances safety, and lowers repair costs. By integrating these Hydraulic rotary joint maintenance guides and maintenance strategies, industries can optimize their hydraulic rotary joints’ performance and reliability, keeping their operations running smoothly and efficiently.