Showing all 39 resultsSorted by price: high to low

-

Sale!

$280.00 Original price was: $280.00.$270.00Current price is: $270.00.

- Max Pressure (Air): 150 PSI

- Max Pressure (Vacuum): -13.75 PSI

- Max Flow Rate (Air): Up to 300 CFM

- Overall Length: Varies by model

- Rotor Connection: Various options available (e.g., G 1/4″-19)

- Operating Temperature: Up to 250°F (121°C)

-

Sale!

$260.00 Original price was: $260.00.$240.00Current price is: $240.00.

- Medium: Coolant

- Max. Temperature: 70℃

- Max. Pressure: 50 bar

- Max. Speed: 15000 rpm

- Max. Flow Rate: 28 L/Min

- Medium Purity: <25μ

-

Sale!

$175.00 Original price was: $175.00.$153.60Current price is: $153.60.

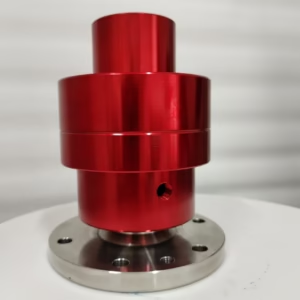

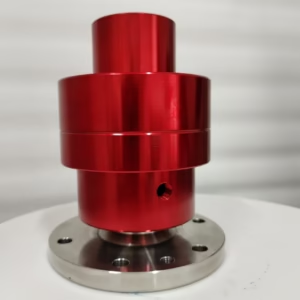

- Media: Water, oil, steam, hot oil, and other media used in molding processes

- Temperature: Ambient to +260°C (+500°F)

- Pressure Rating: Up to 345 bar (5,000 psi) or higher, depending on the model

- Rotational Speed: Up to 1,500 rpm

- Corrosion Resistance: Constructed from stainless steel and specialized alloys

-

Sale!

$130.00 Original price was: $130.00.$116.00Current price is: $116.00.

- Part Number: 902-141-192

- Max Coolant Pressure: 10 bar (145 psi)

- Max Speed:20,000 RPM

- Max Flow Rate:15 l/min (3.96 GPM)

- Max Temperature:70 °C (158 °F)

- Rotor Connection Type: Axial and Radial

-

Sale!

$125.00 Original price was: $125.00.$115.00Current price is: $115.00.

- Part Number:116-610-463

- Supply Connection:1/4″-18 NPT

- Rotor Connection: M16 x 1.5 LH, 17.993 mm pilot

- Overall Length:112 mm

- Housing Diameter: 43.64 mm

- Maximum Pressure: 69 bar (1000 PSI)

- <strong>Maximum Speed: Up to 12000 RPM

-

Sale!

$125.00 Original price was: $125.00.$115.00Current price is: $115.00.

- Size:3/8″

- Max Speed: 12000RPM

- Max Pressure: 70bar

- Max Temperature: 70℃

- Material: stainless steel/carbon steel; aluminum

- Thread: BSPP BSPT NPT METRIC

- Standard: ANSI

- Usage: cooling liquid

-

Sale!

$120.00 Original price was: $120.00.$110.00Current price is: $110.00.

- Maximum Pressure: Up to 400 bar (5800 PSI)

- Maximum Rotational Speed: Up to 42,000 RPM

- Fluid Compatibility: Hydraulic oil, air, water, coolants

- Size Range: Customizable to fit specific needs

- Temperature Range: -20°C to 120°C

-

Sale!

$120.00 Original price was: $120.00.$110.00Current price is: $110.00.

- Compatible Model: Deublin 1116-555-463

- Max Speed: 8000 RPM

- Application: CNC Drilling, Coolant Through Spindle

- Media Supported: Coolant, Air, Water

- Port Size: 1/2” NPT

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

- Part Number: 1109 021 188

- Max Pressure: 210 bar (3,000 psi)

- Max Speed: 20,000 RPM

- Media: Water, Steam, Hydraulic Fluids, Compressed Air

- Materials: Stainless Steel, Brass

- Seals: Mechanical Seals, Silicon Carbide (Optional)

- Channels: Single or Multi-Channel Configurations

- Temperature Range:-40°C to 200°C (-40°F to 392°F)

-

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

- Part Number: 902 121 188

- Max Coolant Pressure: 10 bar

- Max Speed: 20,000 RPM

- Max Flow Rate: 15 l/min

- Connection Type: Axial and Radial

- Material: Anodized Aluminum & SS

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

- Model: 902 120 188

- Max Operating Pressure: 145 PSI (10 bar)

- Max Speed: Up to 20,000 RPM

- Max Flow Rate: Up to 4.1 GPM (15 l/min)</li>

- Max Temperature: Up to 70°C

- Housing Material: Anodized aluminum

- Rotor Material: Stainless steel

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

- Supply Connection: 3/8″-18 NPT

- Rotor Connection: 5/8″-18 UNF LH

- Overall Length: 135 mm (5.315 inches)

- Housing Diameter: 53.5 mm (2.106 inches)

- Maximum Pressure (MQL):10 bar (150 psi)

- Maximum Speed: 20,000 RPM

- Operating Temperature: Up to 71°C (160°F)

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

- Model: Compatible with Deublin 1109-040-188

- Max Pressure: 210 bar (3,000 psi)

- Max Speed: 20,000 RPM

- Media: Water, Steam, Hydraulic Fluids, Compressed Air

- Materials: Stainless Steel, Brass

- Seals: Mechanical Seals, Silicon Carbide (Optional)

- Channels: Single or Multi-Channel Configurations

- Temperature Range: -40°C to 200°C (-40°F to 392°F)

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

Temperature Range:

-40°C to 200°C (-40°F to 392°F)

-

Sale!

$120.00 Original price was: $120.00.$108.00Current price is: $108.00.

-

Sale!

$100.00 Original price was: $100.00.$96.00Current price is: $96.00.

- Compatible Model: Deublin 1101-195-343 Rotary Union

- Media: Steam, water, hot oil, compressed air

- Max. Temperature: -30°C to +300°C (-22°F to +572°F)

- Max. Pressure: Up to 25 bar (362 psi)

- Max. Speed: Up to 3,500 RPM

- Connection Type: Threaded / Flanged

- Housing Material: Stainless steel/carbon steel

- Seal Type: Mechanical seal (carbon graphite/ceramic)

- Sizes Available: Standard + custom sizes available

-

Sale!

$100.00 Original price was: $100.00.$91.00Current price is: $91.00.

- Model: A10/A08

- Medium: Hydraulic oil/Coolant

- Pressure: ≤7.0 MPa

- Rotational Speed: ≤8000 RPM

- Temperature: <71°C (For high-temperature applications, please contact us)

-

Sale!

$100.00 Original price was: $100.00.$91.00Current price is: $91.00.

- Model: A10-1771-05L

- Connection Size: 1/4″ NPT/BSPP (threaded)

- Max Pressure: 20 bar (290 psi)

- Max Speed: 10,000 RPM

- Material: Stainless steel & anodized aluminum

- Temperature Range: -20°C to 80°C

- Media: Compressed air, oils, coolants

- Weight: 0.5 kg

-

Sale!

$100.00 Original price was: $100.00.$90.00Current price is: $90.00.

- Maximum Pressure: Up to 400 bar (5800 PSI)

- Maximum Rotational Speed: Up to 42,000 RPM

- Fluid Compatibility: Hydraulic oil, air, water, coolants

- Size Range: Customizable to fit specific needs

- Temperature Range: -20°C to 120°C

-

Sale!

$90.00 Original price was: $90.00.$81.00Current price is: $81.00.

- Material:Stainless steel

- Max.Speed:7000RPM

- Max. Pressure:5.0MPa

- Max.Temperature:100℃

- Applicable Medium:Water, Coolant, Hydraulic Fluid

-

Sale!

$80.00 Original price was: $80.00.$77.00Current price is: $77.00.

- Part Number: 1116-048-143

- Max Pressure:210 bar (3,000 psi)

- Max Speed:6,000 RPM

- Media Compatibility:Water, Steam, Hydraulic Fluids, Compressed Air

- Materials: Stainless Steel, Brass

- Seals:Mechanical Seals, Silicon Carbide (Optional)

- Channels:Single or Multi-Channel Configurations

- Temperature Range:-40°C to 200°C (-40°F to 392°F)

- Dimensions:Compact design suitable for tight spaces

- Mounting Options:Various configurations for different installation requirements

-

Sale!

$60.00 Original price was: $60.00.$58.00Current price is: $58.00.

- Medium: Coolant

- Max.Pressure: 70bar

- Max.Speed: 12000rpm

- Max.Temperature: 80℃

- Recommended Filtration: 0.05mm

- Special Feature: Dry Operation Available

- Inlet Interface: G3/8 -19

- Drain Interface: Φ8

- Thread Specification: M16*1.5LH

-

Sale!

$60.00 Original price was: $60.00.$55.00Current price is: $55.00.

- Size Range: 1/8″ (DN06) to 1 1/2″ (DN40)

- Maximum Pressure: Up to 400 bar

- Maximum Temperature: Up to 120°C

- Speed Capability: High-speed options available

- Thread Types: LH & RH UNF, Metric, BSP & NPT

-

Sale!

$60.00 Original price was: $60.00.$55.00Current price is: $55.00.

- Max Rotational Speed: Up to 42,000 RPM

- Max Pressure: Up to 250 bar

- Nominal Size: 0.1 in – 0.5 in

- Media Types: Supported Coolant, air, hydraulic oil

- Temperature Range: -20°C to 100°C

-

Sale!

$60.00 Original price was: $60.00.$55.00Current price is: $55.00.

- Material:Stainless steel/copper

- Pipe Clamp Size:16/20/25

- Max.Speed:100RPM

- Max. Pressure:1.8MPa

- Max. Temperature:220°C

- Applicable Medium:Over hot water, oil

-

Sale!

$40.00 Original price was: $40.00.$35.00Current price is: $35.00.

- Size:6A/8A/10A/15A

- Max. Speed:2000-3800RPM

- Max. Pressure:1.5-3MPA&amp;lt;/li>

- Max. Temperature:100 degrees (High temperature can be customized)</li>

- <strong>Suitable medium:Gas, compressed air, water, hydraulic oil, coolant

-

Sale!

$40.00 Original price was: $40.00.$35.00Current price is: $35.00.

- Max.Speed: ≤3000RPM

- Max. Pressure: ≤1.5MPA

- Max Temperature: ≤150℃

- Applicable medium: Water, AIR, Oxygen, Hydrogen, etc

-

Sale!

$35.00 Original price was: $35.00.$31.00Current price is: $31.00.

- Size Range: 1/8″(DN06) to 1 1/2″ (DN40)

- Maximum Pressure: Up to 400 bar

- Maximum Temperature: Up to 120°C

- Speed Capability: High-speed options available

- Thread Types: LH & RH UNF, Metric, BSP & NPT

-

Sale!

$35.00 Original price was: $35.00.$31.00Current price is: $31.00.

- Material: Stainless Steel (SS304/316)

- Size: 1/8″ – 4″ NPT (customizable)

- Max Pressure: Up to 7,500 PSI (515 BAR)

- Max Temperature: Up to 220°C (428°F)

- Max Speed: Up to 500 RPM

- Passages: 1, 2, 3 or more

- Media: Oil, Water, Air, Coolant, Gas

-

Sale!

$40.00 Original price was: $40.00.$30.00Current price is: $30.00.

- Maximum Air Pressure: Up to 250 PSI

- Maximum Rotational Speed: Up to 4,000 RPM

- Maximum Temperature: Up to 225°F (107°C)

- Seal Type: Silicon carbide to carbon graphite

- Material Options: Stainless Steel, Hastelloy

- Thread Types: NPT, BSP, Metric, and others

- Passage Options: Single or multiple air passages

-

Sale!

$35.00 Original price was: $35.00.$30.00Current price is: $30.00.

- Max Pressure: Up to 10 bar (145 psi)

- Max Temperature: Up to 80°C (176°F)

- Rotational Speed: Up to 3,000 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

-

Sale!

$35.00 Original price was: $35.00.$30.00Current price is: $30.00.

- Max Pressure: Up to 10 bar (145 psi)

- Max Temperature: Up to 80°C (176°F)

- Rotational Speed: Up to 3,000 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

-

Sale!

$25.00 Original price was: $25.00.$23.00Current price is: $23.00.

- Applicable media: Coolant, hot water, cold water, oil, compressed air, low-pressure steam.

- Maximum pressure: 2.0 MPa

- Maximum temperature: 120°C (varies depending on port size)

- Maximum rotational speed: 2000 rpm – 3000 rpm

-

Sale!

$20.00 Original price was: $20.00.$15.00Current price is: $15.00.

- Product Name: H Type Fluid Rotary Joint

- Media Supported:</strong> Steam, Water, Hot Oil, Air, Coolant

- Working Pressure: Up to 30 bar / 435 PSI

- Rotational Speed: Up to 3000 RPM

- Temperature Range: -20°C to 250°C

- Number of Passages: Single or Dual

- Body Material: Carbon Steel / Stainless Steel / Cast Iron

-

- Medium: Air

- Max. Temperature: 25℃

- Max. Pressure: 8 bar

- Max. Speed: 1500 rpm

- Stationary Port Thread Size: 1/8 “

-

- Medium: Oil

- Max. Temperature: 120℃

- Max. Pressure: 200Bar

- Max. Speed: 250RPM

- Housing Material: Aluminum

- Application: General Industry

-

- Model Number: Deublin 1109-840-835

- Union Type: Monoflow Bearingless Rotary Union

- Rotor Connection: 3/4″ NPT, Right-Hand Thread

- Housing Connection: 1/4″ NPT

- Max. Coolant Pressure: 1,500 PSI (103 bar)

- Max. Speed: 10,000 RPM

- Max. Temperature: 250°F (120°C)

- Media Compatibility: Coolant, Cutting Fluid, MQL (Air/Oil Mist)

- Seal Face Combination: Silicon Carbide / Silicon Carbide (SiC/SiC)

- Housing Material: Anodized Aluminum

- Rotor Material: Hardened Steel

-

- Model Number: Deublin 902-137-188 Rotary Union

- Type: Dual-Passage Rotary Union

- Connection Size: 3/8″ NPT (Inlet & Outlet)

- Media: Air, Water, Coolant, Hydraulic Oil, Steam

- Seal Material: Carbon-Graphite / Silicon Carbide

- Bearing Type: Precision Ball Bearings

- Maximum Speed: Up to 3,000 RPM

- Maximum Pressure: 150 PSI (10 bar) – varies by media

- Operating Temperature: -20°C to 180°C (-4°F to 356°F)

- Housing Material: Hardened Steel / Stainless Steel

-

- Model Number: 1101

- Flow Direction: Single-Flow

- Inlet Type: NPT BSP ORB

- Applicable medium: Coolant

- Coolant Max. Pressure: 105bar

- Coolant Max. Temperature: 71 °C

- Max. Speed: 15000rpm