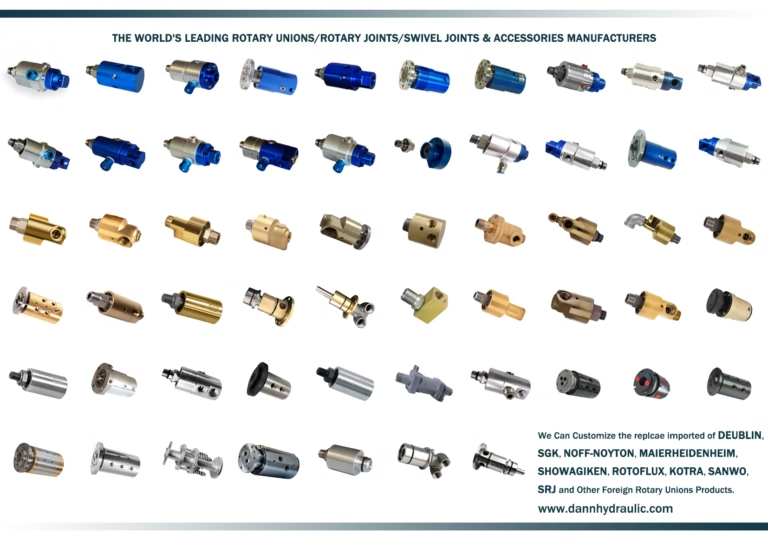

Dedicated Rotary Unions for Fog Cannons & Tower Crane Sprayers

In the realm of industrial dust suppression and air quality management, fog cannons and tower crane sprayers stand as critical equipment. These systems combat airborne particles, control emissions, and maintain safe working environments across construction sites, ports, mines, and manufacturing facilities. At the heart of their efficient operation lies an often overlooked component: the dedicated rotary unions. This specialized component enables seamless fluid transfer between stationary supply lines and rotating spray mechanisms, ensuring consistent performance even in demanding conditions. This blog explores the design, functionality, applications, and maintenance of dedicated rotary unions for fog cannons and tower crane sprayers, highlighting their indispensable role in modern industrial air quality solutions.

Understanding the Role of Dedicated Rotary Unions in Spraying Systems

Fog cannons and tower crane sprayers operate on a simple yet effective principle: they atomize water (or water-based solutions) into fine droplets that capture airborne dust particles, forcing them to settle. Unlike fixed sprinkler systems, these machines require rotational movement to cover large areas—from 30 to over 100 meters in radius. This rotation demands a critical connection point that allows water to flow continuously while the spray nozzle assembly turns: the dedicated rotary joint.

Core Functionality

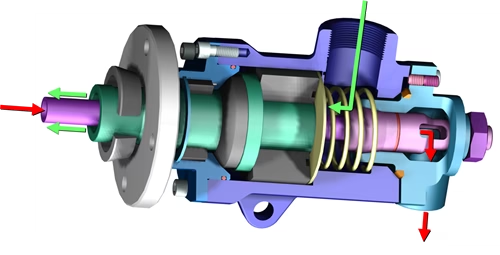

Dedicated rotary unions for fog cannons and tower crane sprayers serve as the bridge between two components in relative motion: the stationary water supply hose and the rotating spray arm or cannon barrel. It must maintain a watertight seal across a range of pressures (typically 3–15 bar for fog cannons, up to 20 bar for high-pressure tower systems) while accommodating rotational speeds of 5–30 RPM.

In operation, water enters the stationary portion of the joint through an inlet port, flows through internal channels, and exits through the rotating outlet connected to the spray mechanism. Precision-engineered seals prevent leakage at the interface between moving and stationary parts, even as the sprayer oscillates or rotates 360 degrees. This continuous flow ensures uniform droplet distribution, maximizing dust suppression efficiency.

Key Design Considerations

Manufacturers tailor these rotary joints to the unique demands of spraying applications:

Flow Rate Optimization:

Internal pathways match the sprayer’s water requirements, typically 50–500 liters per minute, to avoid pressure drops that would reduce atomization quality.

Rotation Range:

Tower crane sprayers often require full 360° rotation, while fog cannons may oscillate through 90°–180° arcs. Joints feature bearings rated for continuous or intermittent rotational patterns.

Environmental Resistance:

Exposure to dust, debris, and weather (rain, UV radiation) necessitates robust housing materials like galvanized steel or stainless steel (304 or 316 grades for coastal/chemical environments).

Technical Features of High-Performance Rotary Joints

The effectiveness of fog cannons and tower crane sprayers directly depends on the reliability of their rotary joints. Superior designs incorporate features that address the specific challenges of dust suppression environments:

Pressure Handling Capabilities

Industrial sprayers operate under varying pressure conditions to adjust droplet size—lower pressure (3–7 bar) produces larger droplets for heavy dust, while higher pressure (8–15 bar) creates finer mist for suspended particles. Dedicated rotary joints must maintain integrity across this range without leakage or pressure loss.

Advanced models use balanced mechanical seals with spring-loaded faces (typically carbon vs. stainless steel or ceramic) that adjust to pressure fluctuations. This design ensures consistent sealing even when water pressure spikes, a common occurrence when sprayers start or change direction.

Material Selection for Durability

The harsh operating environments of construction sites and mines demand materials that resist corrosion, abrasion, and impact:

Housings:

Galvanized steel provides cost-effective protection against rust for general applications. Stainless steel (316) offers superior resistance to saltwater and chemical additives (like surfactants used in some dust suppression solutions).

Seals:

Nitrile rubber works well for standard water applications, while Viton® seals handle higher temperatures and chemical exposure. PTFE (Teflon®) seals offer low friction and compatibility with aggressive cleaning agents.

Bearings:

Sealed ball bearings or roller bearings with grease fittings withstand continuous rotation and prevent contamination from dust and water.

Compact Design for Integration

Fog cannons and tower crane sprayers have limited space for auxiliary components. Dedicated rotary joints feature compact, low-profile designs that fit within the sprayer’s mechanical housing without interfering with rotation. Many models include flanged or threaded connections for quick installation, reducing downtime during maintenance or replacement.

Applications Across Industries: Where Rotary Joints Make a Difference

Dedicated rotary unions for fog cannons and tower crane sprayers find application in diverse sectors where dust control is critical for safety, regulatory compliance, and operational efficiency.

Construction and Demolition Sites

Construction activities—demolition, concrete cutting, and earthmoving—generate massive amounts of particulate matter. Tower crane sprayers, mounted on crane booms 30–80 meters high, cover entire job sites with water mist, while fog cannons target specific work zones.

In these environments, rotary joints must withstand constant vibration from crane operations and exposure to concrete dust, which can abrade seals. A well-designed joint ensures uninterrupted operation, preventing costly shutdowns for dust-related regulatory violations. For example, a high-rise construction project in an urban area might use a tower crane sprayer with a stainless steel rotary joint to comply with local air quality standards, avoiding fines and maintaining community relations.

Ports and Bulk Material Handling

Ports and material handling facilities transfer bulk commodities like coal, ore, and grain, creating clouds of respirable dust. Fog cannons positioned near conveyor belts, ship loaders, and storage piles suppress dust at its source.

Rotary unions in these applications face unique challenges: saltwater exposure in coastal ports and abrasive dust particles that can infiltrate moving parts. Marine-grade rotary unions with 316 stainless steel construction and double-lip seals prevent corrosion and contamination, ensuring reliable performance in 24/7 operations. A coal export terminal, for instance, might deploy fog cannons with reinforced rotary joints to handle high-pressure water (12–15 bar) and continuous rotation, reducing dust emissions by up to 80%.

Mining Operations

Surface mining (quarries, open-pit mines) and underground mining generate hazardous dust containing silica, which poses severe health risks to workers. Fog cannons mounted on mobile platforms or fixed structures control dust during drilling, blasting, and material transport.

Mining environments demand the most robust rotary joints, as they face extreme vibration, heavy dust loads, and occasional exposure to chemicals (like dust-binding agents). Joints with reinforced housings, oversized bearings, and self-cleaning seal designs excel here. A limestone quarry might use a large fog cannon (coverage radius 80+ meters) with heavy-duty rotary unions to protect workers from silica dust, reducing respiratory health incidents and improving compliance with mining safety regulations.

Waste Management Facilities

Landfills and waste transfer stations produce dust from decomposing materials and vehicle traffic. Tower crane sprayers mounted on landfill boundaries or transfer station roofs control dust spread to surrounding communities.

Rotary unions in waste management applications must resist corrosion from landfill leachate and bacteria. Sealed designs with Viton® seals and corrosion-resistant coatings ensure longevity. A municipal landfill, for example, could integrate a tower crane sprayer with a dedicated rotary joint to maintain dust levels below regulatory thresholds, minimizing complaints from nearby residents.

Advantages of Using Dedicated vs. Generic Rotary Joints

While generic rotary unions might seem like a cost-saving option, dedicated models engineered for fog cannons and tower crane sprayers offer significant advantages:

Improved Spray Consistency

Dedicated joints match the flow rate and pressure requirements of specific sprayer models, eliminating pressure drops that cause uneven droplet distribution. This consistency ensures uniform dust suppression across the target area, reducing hotspots where dust concentrations exceed safe limits.

Longer Service Life

Generic joints often fail prematurely in sprayer applications due to incompatible materials or inadequate sealing. Dedicated designs use application-specific materials (e.g., corrosion-resistant alloys, chemical-resistant seals) and reinforced bearings, doubling or tripling service life. In a busy port facility, this could mean extending maintenance intervals from 3 months to 12 months, reducing downtime and labor costs.

Reduced Maintenance Requirements

Dedicated rotary unions feature user-friendly maintenance features: grease fittings for bearings, easy-access seal replacement, and visual indicators for wear. This simplifies upkeep, allowing on-site technicians to perform repairs instead of requiring specialized contractors. For remote mining operations, this translates to faster turnaround times and lower maintenance expenses.

Enhanced Safety

Leakage from generic joints can create slippery surfaces around equipment, increasing fall risks. Dedicated designs with robust sealing systems prevent water leakage, maintaining safe working conditions. Additionally, reliable fluid transfer ensures sprayers operate at peak efficiency, reducing worker exposure to harmful dust.

Installation and Maintenance Best Practices

Proper installation and maintenance maximize the performance and lifespan of dedicated rotary unions for fog cannons and tower crane sprayers.

Installation Guidelines

Alignment:

Ensure the rotary union aligns perfectly with both the stationary water supply and the rotating spray arm. Misalignment causes uneven wear on seals and bearings, leading to premature failure. Use precision shims if necessary to achieve concentric alignment.

Torque Specifications:

Follow manufacturer recommendations for tightening flange bolts or threaded connections. Over-tightening can warp sealing surfaces, while under-tightening may cause leaks.

Pressure Testing:

After installation, test the system at operating pressure (with the sprayer stationary) to check for leaks. Rotate the sprayer through its full range of motion while monitoring for pressure drops or unusual sounds, which indicate installation issues.

Protection:

Install protective covers or guards around the rotary union to shield it from impact, falling debris, and direct sunlight (which can degrade rubber seals over time).

Maintenance Protocols

Regular Inspections:

Conduct visual checks weekly for leaks, corrosion, or damage. For high-use equipment (24/7 operations), increase inspections to twice weekly. Look for signs of seal wear, such as water seepage around the rotation interface.

Lubrication:

Grease bearings every 50–100 hours of operation using a high-quality, water-resistant lubricant (e.g., lithium complex grease). Avoid over-greasing, which can attract dust and debris.

Seal Replacement:

Replace seals at the first sign of leakage or according to the manufacturer’s schedule (typically every 6–12 months, depending on usage). Use only OEM replacement seals to ensure compatibility and performance.

Cleaning:

Periodically flush the rotary joint with clean water to remove sediment or debris that could scratch sealing surfaces. For applications with abrasive dust, consider installing in-line filters to protect the joint from contamination.

Winterization:

In cold climates, drain water from the rotary union and sprayer system when not in use to prevent freezing damage. Use compressed air to clear all water from internal channels.

Troubleshooting Common Issues

Even with proper maintenance, rotary unions may encounter problems. Early diagnosis and resolution prevent minor issues from escalating into major failures:

Leakage at the Rotation Interface

Possible Causes:

Worn seals, misalignment, or debris on sealing surfaces. –

Solution:

Inspect seals for wear and replace if necessary. Check alignment and realign if needed. Clean sealing surfaces with a soft cloth and mild detergent.

Reduced Flow or Pressure

Possible Causes:

Blockage in internal channels, damaged bearings restricting rotation, or partially closed supply valves.

Solution:

Flush the joint to remove blockages. Check bearings for damage and replace if seized or noisy. Verify supply valves are fully open.

Unusual Noise During Rotation

Possible Causes:

Dry or damaged bearings, misalignment, or foreign debris in the joint.

Solution:

Lubricate bearings. Check alignment and remove any debris. Replace bearings if noise persists after lubrication.

Corrosion

Possible Causes:

Exposure to saltwater, chemicals, or harsh weather without proper protection.

Solution:

Replace corroded components with materials suited to the environment (e.g., 316 stainless steel for saltwater). Apply anti-corrosion coatings to exposed surfaces.

Future Trends in Rotary Joint Technology for Spraying Systems

As industries adopt stricter environmental standards and seek greater efficiency, rotary joint technology continues to evolve:

Smart Monitoring Integration

Manufacturers are developing rotary joints with embedded sensors that monitor temperature, vibration, and pressure differentials. These sensors transmit data to a central system, alerting operators to potential issues (e.g., seal wear, bearing failure) before they cause downtime. In smart construction sites, this predictive maintenance could reduce unplanned shutdowns by up to 30%.

Material Innovations

Advancements in materials science are leading to more durable components:

Graphene-Enhanced Seals:

Offer superior wear resistance and longer life compared to traditional rubber seals.

Ceramic Bearings:

Provide better corrosion resistance and higher temperature tolerance than steel bearings, suitable for extreme environments.

Self-Healing Coatings:

Housings with these coatings automatically repair minor scratches, preventing corrosion from taking hold.

Energy Efficiency Improvements

Low-friction designs reduce the energy required to rotate spray mechanisms, lowering operational costs