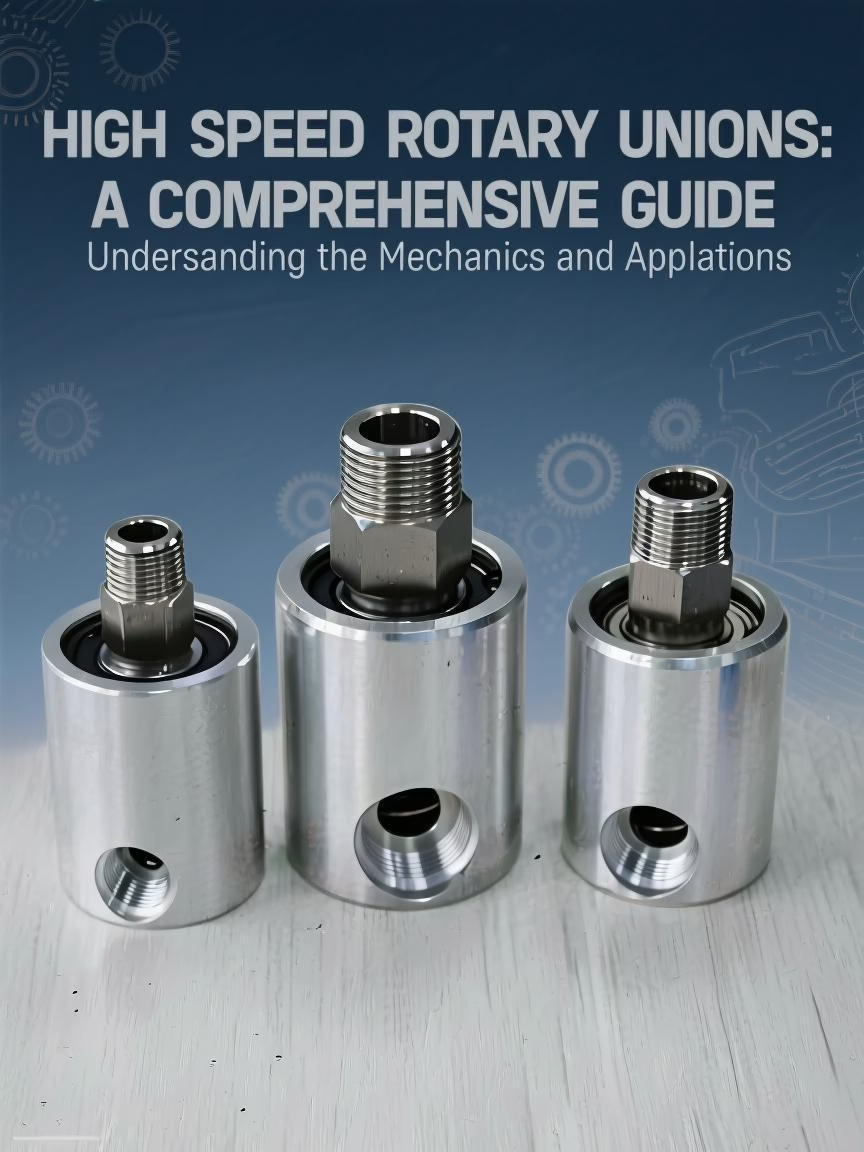

High Speed Rotary Unions: A Comprehensive Guide

In today’s high-performance industrial world, high-speed rotary unions have become essential components in a variety of rotating machinery. These precision-engineered devices enable the safe and efficient transfer of fluids or gases—such as air, oil, steam, or coolant—from stationary sources to rotating equipment parts. Whether you’re in manufacturing, aerospace, packaging, robotics, or CNC machining, the role of a rotary union cannot be overstated.

This guide will walk engineers, technical buyers, and maintenance professionals through the types, materials, features, and applications of high-speed rotary unions—along with a comparative chart and practical selection tips. This guide covers everything you need to know about high-speed rotary unions: how they work, where engineers apply them, their key design features, how to select the right model, tips for maintenance, and answers to frequently asked questions.

Technical Overview of High-Speed Rotary Unions

Technical Overview of High-Speed Rotary Unions

A high-speed rotary union (also called a rotary joint, rotary coupling, or rotary swivel) is a mechanical device that allows the transmission of a fluid (liquid or gas) into or out of a rotating part, without twisting hoses or leaking under pressure. It is a precision mechanical device that enables the transfer of fluid (oil, water, coolant, air, etc.) between stationary supply lines and rotating components at elevated RPMs, often above 5,000 RPM and reaching up to 30,000 RPM in extreme conditions. They are often used in CNC machining, automated tool changers, laser cutting, and high-frequency spindles.

Unlike standard rotary unions, high-speed versions are designed to maintain seal integrity and fluid flow at elevated rotation speeds, sometimes exceeding 10,000 RPM. They often feature low-friction seals, balanced components, and lightweight materials like anodized aluminum, stainless steel, or carbon fiber to reduce heat buildup and wear.

Key Components

Sealing Mechanisms

Mechanical Seals:

One of the most critical components of a high-speed rotary union is the mechanical seal. These seals are designed to prevent fluid leakage between the stationary and rotating parts of the union. Mechanical seals typically consist of two sealing faces, one stationary and one rotating, that are held in close contact with each other.

Manufacturers use sealing faces made from materials such as carbon graphite, silicon carbide, or tungsten carbide to ensure excellent wear resistance, low friction, and high-temperature stability. For example, in a high-speed machine tool spindle, the system transfers coolant through a rotary union. The mechanical seal directs the coolant precisely to the cutting tool without leakage, maintaining optimal performance and preventing potential damage to the equipment.

O-Rings and Gaskets:

In addition to mechanical seals, high-speed rotary unions often incorporate O-rings and gaskets. Engineers use gaskets as flat or shaped seals placed between flanges or other mating surfaces to prevent leakage. Engineers select gasket materials—such as nitrile rubber, fluorocarbon rubber, or silicone rubber—by evaluating the fluid’s chemical properties and the system’s operating temperature and pressure conditions.

They use gaskets as flat or shaped seals placed between flanges or other mating surfaces to prevent leakage. They select gasket materials—such as nitrile rubber, fluorocarbon rubber, or silicone rubber—based on the chemical compatibility with the fluid being transferred and the system’s operating temperature and pressure conditions.

Bearings

Ball Bearings:

Ball bearings are widely used in high-speed rotary unions due to their ability to support high rotational speeds with low friction. They consist of a set of balls that are held between two raceways, allowing for smooth rotation.

Ball bearings are available in various types, such as deep groove ball bearings, angular contact ball bearings, and thrust ball bearings. Deep-groove ball bearings are for applications where the radial load is the primary concern, while angular contact ball bearings can handle both radial and axial loads. Manufacturers design thrust ball bearings specifically to support axial loads. In a high-speed printing press, for instance, ball bearings in the rotary union enable the smooth transfer of ink or other fluids to the rotating cylinders. It ensures accurate printing at high speeds.

Roller Bearings:

Roller bearings, including cylindrical roller bearings, tapered roller bearings, and spherical roller bearings. They are also used in rotary unions, especially in applications where higher load-carrying capacities are required. Cylindrical roller bearings are well-suited for applications with high radial loads. Tapered roller bearings can handle both radial and axial loads simultaneously. Spherical roller bearings accommodate misalignment for applications where shaft deflection may occur. In a high-speed industrial mixer, roller bearings in the rotary union support the heavy rotating parts and the forces generated during the mixing process. It allows for efficient operation.

Shaft and Housing

Shaft:

The shaft of a high-speed rotary union transfers fluid and rotates around its axis. Manufacturers typically make shafts from high-strength materials such as stainless steel, alloy steel, or titanium, depending on the application requirements. Machinists precisely machine the shaft to ensure smooth rotation and proper alignment with the other rotary union components. Additionally, engineers apply special coatings or surface finishes to the shaft to enhance its wear resistance and corrosion resistance. For example, in a high-speed steam turbine, designers use high-temperature-resistant alloy steel for the rotary union shaft to withstand extreme conditions of high-pressure steam and rapid rotation.

Housing:

The housing of a high-speed rotary union encloses and protects the internal components. Such as the seals and bearings. It also provides the connection points for the fluid inlet and outlet pipes. Housings are usually with materials such as cast iron, steel, or aluminum alloy. Cast iron housings offer good strength and vibration-damping properties. While steel housings are known for their high strength and durability. Aluminum alloy housings are lightweight and are for applications where weight reduction is a critical factor. The housing design may also incorporate features such as cooling fins. Engineers use jackets to dissipate heat generated during operation, especially in applications where high-temperature fluids are transferred.

Working Principle

The working principle of a high-speed rotary union is the ability to maintain a fluid-tight connection between a stationary and a rotating component. That allows for the transfer of fluids. As the rotating part of the machine (such as a spindle, drum, or cylinder) rotates. The high-speed rotary union continuously supplies fluid to the rotating component without leakage.

The fluid enters the rotary union through a stationary inlet port. The internal components of the union, such as the seals and bearings. They allow the fluid to pass through and directly to the rotating part. The mechanical seals prevent the fluid from escaping between the stationary and rotating parts. The bearings support the rotation of the shaft and ensure smooth operation. The fluid then exits the rotary union through a rotating outlet port and goes to the intended destination within the rotating part of the machine.

As the equipment spins, the rotary union uses precision bearings and dynamic seals to maintain a leak-proof connection. This ensures a continuous flow of coolant, oil, steam, air, or vacuum without restricting rotation or causing pressure loss.

Many modern units also include features like:

Labyrinth seals or mechanical face seals

Carbon-graphite sealing rings

Integrated slip rings for data/signal transfer

Balanced rotating assemblies for vibration control

Types of High-Speed Rotary Unions

There are several types of high-speed rotary unions available, each designed to meet specific application requirements. Some of the common types include:

Single-Passage High-Speed Rotary Unions

Single-passage high-speed rotary unions are the simplest type, designed to transfer a single fluid from a stationary source to a rotating component. They have a single inlet and a single outlet for the fluid. Engineers commonly use these unions in applications where they transfer only one type of fluid, such as coolant in basic machine tools. For example, in a small-scale machining operation, technicians install a single-pass high-speed rotary union to supply coolant directly to the cutting tool. The design of a single-passage rotary union is relatively straightforward, with a focus on ensuring a reliable seal and smooth rotation for the transfer of the fluid.

Multi-Passage High-Speed Rotary Unions

Multi-passage high-speed rotary unions transfer multiple fluids simultaneously. They have multiple inlets and outlets, allowing for the independent transfer of different fluids, such as water, oil, and air. These unions are for complex fluid transfer requirements. For instance, in a high-speed industrial dryer, a multi-passage rotary union can transfer steam for heating., Also, it can transfer cooling water for temperature control, and compressed air for cleaning or drying purposes. The internal design of a multi-passage rotary union is more complex. It needs to ensure that the different fluids do not mix and that each fluid is transferred efficiently to its intended destination.

High-Pressure High-Speed Rotary Unions

Rotary unions are specifically for handling high-pressure fluids while operating at high rotational speeds. These union applications such as hydraulic systems in heavy machinery or high-pressure steam transfer in power generation. The materials in the construction of high-pressure high-speed rotary unions withstand the high pressures, and the sealing mechanisms maintain a leak-free connection under extreme conditions. For example, a hydraulic press is used in the metalworking industry. A high-pressure, high-speed rotary union that transfers hydraulic fluid at high pressures to the rotating cylinders, enabling the press to exert high forces on the metal workpieces.

High-Temperature High-Speed Rotary Unions

Rotary unions transfer fluids at elevated temperatures, such as in steam-based processes or high-temperature heat transfer applications. Manufacturers select materials for these unions—especially seals, bearings, and housings—based on their high-temperature resistance. For instance, in a steam turbine, where steam temperatures can reach several hundred degrees Celsius, a high-temperature high-speed rotary union transfers steam to the rotating blades. These unions typically use seals made from materials like graphite or special high-temperature-resistant polymers, while engineers design the bearings to operate smoothly at high temperatures.

Applications of High-Speed Rotary Unions

High-speed rotary unions find applications in a wide range of industries, including steel, metallurgy, paper, glass, printing and dyeing, chemical, pharmaceutical, petroleum, tobacco, food, plastic, and rubber. Equipment such as paper machines, drying machines, mixing machines, and injection molding machines uses them. The versatility of high-speed rotary unions makes them an essential component in many industrial processes.

Case Studies in High-Speed Rotary Unions

Real-world case studies demonstrate the effectiveness of high-speed rotary unions in various applications. For example, in the steel industry, high-speed rotary unions transfer coolant to rolling mills. It can help improve the quality of the finished product. In the paper industry, they transfer steam to drying rolls. It can help improve the efficiency of the paper-making process. These case studies highlight the versatility and importance of high-speed rotary unions in modern industry.

Selection Guide for High-Speed Rotary Unions

Selecting the right high-speed rotary union for your application involves considering several factors. It includes the type of fluid you transfer, the operating pressure and temperature, the speed of rotation, and the flow rate you require. It is also important to consider the material compatibility and the environmental conditions in which the union will operate. Consulting with a qualified engineer or manufacturer can help ensure that you select the most appropriate high-speed rotary union for your needs.

Maintenance Tips for High-Speed Rotary Unions

Proper maintenance is crucial for ensuring the longevity and reliability of high-speed rotary unions. Regular cleaning, lubrication, and inspection can help prevent failures and minimize downtime. It is also important to follow the manufacturer’s recommendations for maintenance intervals and procedures. By adhering to these guidelines, you can help ensure that your high-speed rotary unions operate efficiently and effectively for years to come.

Future Trends in High-Speed Rotary Unions

The future of high-speed rotary unions looks bright, with ongoing advancements in materials science, manufacturing techniques, and design. These advancements are leading to the development of more efficient, reliable, and durable high-speed rotary unions. As industries continue to evolve and demand for high-performance fluid transfer solutions grows. High-speed rotary unions play an increasingly important role in the future of industrial automation and process control.

Conclusion

High-speed rotary unions are indispensable components in modern manufacturing and processing industries. Their ability to transfer fluids securely and efficiently at very high rotation speeds enables critical processes to run smoothly, safely, and with minimal downtime. Understanding the critical design features, selecting the right type tailored to your specific application, and adhering to best practices in installation and maintenance will ensure long-term operational success. With the integration of advanced sealing technologies and robust materials, today’s high-speed rotary unions offer reliability even in the most demanding industrial environments.

For engineers, technical personnel, and procurement professionals, an informed choice of a high-speed rotary union can significantly impact the efficiency and lifespan of machinery. Properly specified and maintained, these unions safeguard equipment performance, reduce maintenance costs, and support production consistency.

If you want further details about specific models, custom configurations, or installation guidance tailored to your machinery, contact your rotary union supplier or technical expert.

This comprehensive guide to high-speed rotary unions integrates critical keywords and technical insights to improve Google ranking and relevance for professionals seeking trusted information on these essential industrial components.