“Cooling Water Roller Slag Rotary Cooler Tire Rrotary Joint” has been added to your cart.

View cart

Showing 1–40 of 41 resultsSorted by price: high to low

-

Sale!

$300.00 Original price was: $300.00.$291.50Current price is: $291.50.

- Flow Rate: 1 to 20 liters per minute (L/min)

- Pressure Rating: Up to 10 bar (145 psi)

- Temperature Range: 0°C to +60°C (32°F to +140°F)

- Material Construction: Brass, Stainless Steel, High-Quality Plastics

- Sealed Integrity: Durable seals ensure leak-free operation

- Rotational Speed: Up to 100 rpm

-

Sale!

$300.00 Original price was: $300.00.$280.00Current price is: $280.00.

- Max Speed: Up to 10,000 RPM

- Max Pressure: Up to 15 MPa

- Fluid Types: Water, oil, chemicals

- Temperature Range: -20°C to 100°C

-

Sale!

$300.00 Original price was: $300.00.$265.00Current price is: $265.00.

- Material: Stainless Steel (SS316), Carbon Steel

- Pressure Rating: Up to 5000 PSI (customizable for higher pressures)

- Temperature Range: Up to 200°C (392°F) (higher temperatures available upon request)

- Port Sizes: 1/4” to 2” NPT/BSP/DIN (custom sizes available)

- Max RPM: 1000 RPM (higher speeds on request)

-

Sale!

$175.00 Original price was: $175.00.$153.60Current price is: $153.60.

- Media: Water, oil, steam, hot oil, and other media used in molding processes

- Temperature: Ambient to +260°C (+500°F)

- Pressure Rating: Up to 345 bar (5,000 psi) or higher, depending on the model

- Rotational Speed: Up to 1,500 rpm

- Corrosion Resistance: Constructed from stainless steel and specialized alloys

-

Sale!

$130.00 Original price was: $130.00.$118.00Current price is: $118.00.

- Operating Pressure: Up to 300 bar (depending on model)

- Temperature Range: -40°C to +200°C

- Rotation Speed: Maximum rotational speed up to 5000 RPM

- Media Compatibility: Suitable for water, oil, air, steam, and hydraulic fluids

- Connection Options: Various thread types and flange connections available

-

Sale!

$110.00 Original price was: $110.00.$105.00Current price is: $105.00.

- Max.Speed: ≤250RPM

- Max. Pressure: ≤1.5mpa

- Max. Temperature: ≤230℃

- Applicable medium: Coolant,hot water cold water hot oil compressed air

-

Sale!

$110.00 Original price was: $110.00.$105.00Current price is: $105.00.

- Max Speed: 200RPM

- Max Pressure: 1.5Mpa

- Max Temperature: 230℃

- Customized: YES

- Medium: water

- Size:15 20 25

-

Sale!

$120.00 Original price was: $120.00.$100.00Current price is: $100.00.

- Pressure Rating: Up to 15,000 PSI (1000 bar)

- Temperature Range: Designed for extreme temperature variations

- Material Construction: Corrosion-resistant stainless steel

- Sealing Technology: Customizable seals based on application needs

- Maintenance Frequency: Minimal; designed for long service life

-

Sale!

$120.00 Original price was: $120.00.$100.00Current price is: $100.00.

- Pressure Rating: Up to 15,000 PSI (1000 bar)

- Temperature Range: Designed for extreme temperature variations

- Material Construction: Corrosion-resistant stainless steel

- Sealing Technology: Customizable seals based on application needs

- Maintenance Frequency: Minimal; designed for long service life

-

Sale!

$95.00 Original price was: $95.00.$86.00Current price is: $86.00.

- Material: Stainless Steel/Brass/ Carbon steel

- Pressure Rating: Up to 300 BAR

- Temperature Range: -40°C to 120°C

- Port Sizes: Customizable ,from 1/2″ to 4″

- Seal Type:O-ring / Bellows-type seals

-

Sale!

$100.00 Original price was: $100.00.$80.00Current price is: $80.00.

- Pressure Rating: Up to 15,000 PSI (1,000 bar)

- Temperature Range : Suitable for extreme temperature variations

- Material Construction: Corrosion-resistant stainless steel

- Elbow Angle: Available in various angles (e.g., 90°, 180°)

- Sealing Technology: Customizable seals based on application needs

- Maintenance Frequency: Minimal; designed for long service life

-

Sale!

$80.00 Original price was: $80.00.$60.00Current price is: $60.00.

- Part number: Replace Deubin 17-420-401

- Pressure: 2.0MPA

- Temperature: 120℃

- Speed: 3500rpm

- Medium: water, gas, oil

- Installation method: External thread connection

-

Sale!

$80.00 Original price was: $80.00.$60.00Current price is: $60.00.

- Type: Rotary Joint Cylinder Valve

- Pressure Rating: Up to 250 bar

- Material: High-grade alloy steel

- Application: Komori Offset Printing Machines

-

Sale!

$80.00 Original price was: $80.00.$60.00Current price is: $60.00.

- Pressure Rating: Up to 15,000 PSI (1,000 bar)

- Temperature Range: Suitable for extreme temperature variations

- Material Construction: Corrosion-resistant stainless steel

- Sealing Technology :Customizable seals based on application needs

- Maintenance Frequency: Minimal; designed for long service life

-

Sale!

$70.00 Original price was: $70.00.$55.00Current price is: $55.00.

- Material: Stainless Steel 304/316L

- Temperature Range: Up to 220°C (428°F)

- Pressure Range: 0.6 – 1.6 MPa (customizable)

- Connection Type: Flanged or threaded options available

- Shaft Diameter Compatibility: Custom sizes to fit your equipment

-

Sale!

$70.00 Original price was: $70.00.$55.00Current price is: $55.00.

- Speed: ≤100QPM

- Temperature: ≤220℃

- Pressure: ≤1.8MPa

- Applicable medium: steam, heat transfer oil

- Specifications: 20, 25, 32, 40, 50, 65, 80, 100, 125, 150

-

Sale!

$55.00 Original price was: $55.00.$52.00Current price is: $52.00.

- Flow Rate : 1 to 20 liters per minute (L/min)

- Pressure Rating: Up to 10 bar (145 psi)

- Temperature Range: 0°C to +60°C (32°F to +140°F)

- Material Construction: Brass, Stainless Steel, High-Quality Plastics

- Sealed Integrity: Durable seals ensuring leak-free operation

- Rotational Speed: Up to 100 rpm

- Connection Types: Garden hose threads, NPT (National Pipe Thread)

- Durability and Maintenance: Robust design, some models with serviceable seals

-

Sale!

$60.00 Original price was: $60.00.$51.00Current price is: $51.00.

- Product name: Construction Machinery Rotary Union

- Size: Customized Size

- Max.Speed: n≤1000RPM

- Max. Pressure: ≤40bar

- Max. Temperature: ≤250℃

- Applicable medium: Hydraulic oil ,water,air

-

Sale!

$50.00 Original price was: $50.00.$45.00Current price is: $45.00.

- Maximum Pressure: 1.8 MPa (18 bar)

- Maximum Temperature: 220 °C

- Maximum Speed: 150 RPM

- Materials: Cast Iron, Gray Iron, Ductile Iron, 45# Steel

- Seal Type: Q-Face Sealing Structure

-

Sale!

$55.00 Original price was: $55.00.$44.00Current price is: $44.00.

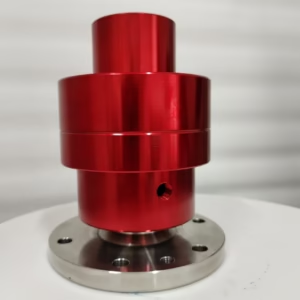

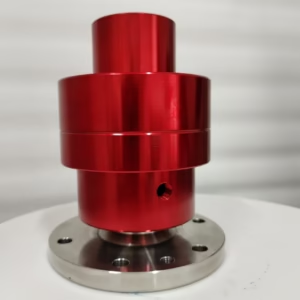

- Max Pressure:5MPa (Vacuum: 0.01torr)

- Operating Temperature:-30°C to 80°C

- Rotational Speed:≤500 RPM

- Service Life:>10 Million Revolutions

- Connection Size:G1/8″, 2”, 3” (customizable)

- Housing Material:Aluminum Alloy (Anodized)

-

Sale!

$50.00 Original price was: $50.00.$42.00Current price is: $42.00.

Water Cooling Rotary Union: Product Details The Water Cooling Rotary Union is an essential component designed to facilitate the efficient transfer of cooling water in various industrial applications. Engineered for high performance and reliability, this rotary union ensures optimal fluid dynamics while preventing leaks, making it ideal for use in manufacturing processes, CNC machines, and…

-

Sale!

$45.00 Original price was: $45.00.$42.00Current price is: $42.00.

- Max.Speed:60RPM

- Max. Pressure:1.2mpa

- Max. Temperature:120 degrees

- Applicable medium:Water, coolant

- Model: Embedded rotary joint for continuous casting machine

-

Sale!

$40.00 Original price was: $40.00.$38.00Current price is: $38.00.

- Max Speed: Up to 42,000 RPM

- Max Pressure: 200 bar

- Media Compatibility: Coolant, water, air, oil

- Seal Materials: Customizable combinations

- Operating Temperature: Up to 121°C (250°F)

-

Sale!

$40.00 Original price was: $40.00.$33.00Current price is: $33.00.

- Flow Rate: 0.5 to 10 liters per minute (L/min)

- Pressure Rating: Up to 20 bar (290 psi)

- Temperature Range : 20°C to +100°C (68°F to +212°F)

- Material Construction: Stainless Steel, Brass, PTFE Seals

- Sealed Integrity: Advanced sealing technology for leak-free operation

- Rotational Speed: Up to 1,000 rpm

- Connection Types: Metric or NPT threads, quick-connect couplings

- Corrosion Resistance: High resistance to chemicals and moisture

- Durability and Maintenance: Robust design with serviceable seals for longevity

-

Sale!

$35.00 Original price was: $35.00.$32.00Current price is: $32.00.

- Product name: High pressure rotary joint

- Size: Customized Size

- Max.Speed: 10-300RPM

- Max. Pressure: 0-35MPA

- Max. Temperature: 40-400ºC

- Medium: Steam, oil, water, air, oxygen, hydrogen, etc

-

Sale!

$35.00 Original price was: $35.00.$30.80Current price is: $30.80.

- Flow Rate: 0.5 to 10 liters per minute (L/min)

- Pressure Rating: Up to 20 bar (290 psi)

- Temperature Range : 20°C to +100°C (68°F to +212°F)

- Material Construction: Stainless Steel, Brass, PTFE Seals

- Sealed Integrity: Advanced sealing technology for leak-free operation

- Rotational Speed: Up to 1,000 rpm

- Connection Types: Metric or NPT threads, quick-connect couplings

- Corrosion Resistance: High resistance to chemicals and moisture

- Durability and Maintenance: Robust design with serviceable seals for longevity

-

Sale!

$35.00 Original price was: $35.00.$30.00Current price is: $30.00.

- Technique: Casting

- Shape: Equal

- Head code: Round

- Surface Treatment: Polished

- Mounting hole diameter: custom

- Pipe Class: Not Rated

- Model number: swivels

- Connectivity: Flange

- Overall Length: 15-60 inches

- Pressure: High pressure

- Pipe Features: Corrosion Resistant

-

Sale!

$35.00 Original price was: $35.00.$30.00Current price is: $30.00.

- Connection: Male

- Product name: Rotary union for paper manufacturing

- Medium: Steam

- Standard: ANSI

- Color: Customized

- Tolerable temperature: 220℃

- Maximum speed: 300RPM

- Apply pressure: 2MPA

-

Sale!

$40.00 Original price was: $40.00.$30.00Current price is: $30.00.

- Connection: Thread/The flange

- Product name: Hot Oil Steam Rotary Joint

- Color: Can be customized

- Medium: Hot water vapor, Steam

- Size: 1/2″~4″

- Surface treatment: Spray paint

- Thread: BSPP BSPT NPT METRIC

- Max Speed: 100RPM

- Max Temperature: 220℃

- Max Pressure: 1.8mpa

-

Sale!

$35.00 Original price was: $35.00.$30.00Current price is: $30.00.

- Technics: Casting

- Thread Standard: NPT\Bsp\Mpt(Customizable)

- Thread Rotation: Left, Right

- Connection Mode: Threaded/Flange Connection

- Max.Speed: 10-50RPM

- Max. Pressure: 1.6-4.0MPA

- Max. Temperature: 100°C

- Medium: Water, hot water, steam, hydraulic oil, thermal oil

-

Sale!

$35.00 Original price was: $35.00.$28.00Current price is: $28.00.

- Maximum speed of use: 120RPM

- Maximum pressure: 1.8MPA

- Maximum temperature :220℃

- Applicable media: water, steam, hot water, etc.

-

Sale!

$30.00 Original price was: $30.00.$27.50Current price is: $27.50.

- Maximum pressure: 1.8MPA

- Maximum temperature :200 degrees Celsius

- Maximum speed :20RPM

- Applicable medium: steam

-

Sale!

$30.00 Original price was: $30.00.$26.00Current price is: $26.00.

- Material: Stainless steel

- Size: All kinds of models and sizes can be customized.

- Max.Speed: ≤200RPM;

- Max. Pressure: ≤35Mpa;

- Max. Temperature: ≤121℃;

- Applicable medium: Hydraulic oil, water, gas, organic solvent.

-

Sale!

$34.00 Original price was: $34.00.$24.80Current price is: $24.80.

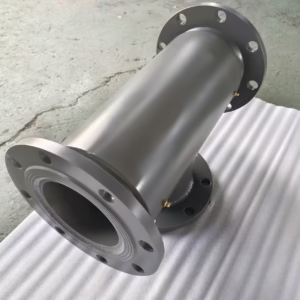

- Withstand pressure: 35MPa

- Rotation speed: 50-3000RPM

- Withstand temperature: 220℃

- Seal type: Imported combination

- Connection size: DN15-DN1000

- Connection method: Flange/Flow

- Medium: water, air, steam, salt water, hydraulic oil alloy steel

- Material: carbon steel, stainless steel, copper

- Bearing brand: SKF/NSK/HRB/WFD

- Application: This product is suitable for oil and gas industry

-

Sale!

$30.00 Original price was: $30.00.$22.00Current price is: $22.00.

- Model number: Q

- Connection: Male

- Medium: Steam

- Standard: ANSI

- Color: Customized

- Tolerable temperature: 220℃

- Maximum speed: 300RPM

- Apply pressure: 2MPA

-

Sale!

$25.00 Original price was: $25.00.$20.50Current price is: $20.50.

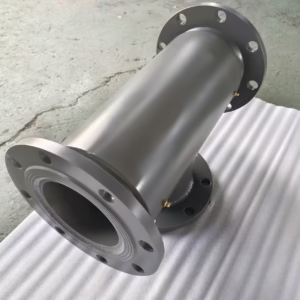

- Product Model: DN/DNF

- Withstand pressure: 35MPa

- Rotation speed: 50-3000RPM

- Withstand temperature: 220℃

- Seal type: Imported combination

- Connection size: DN15-DN1000

- Connection method: Flange/Flow

- Medium: water, air, steam, salt water, hydraulic oil, alloy steel

- Material: carbon steel, stainless steel, copper

- Bearing brand: SKF/NSK/HRB/WFD

-

Sale!

$20.00 Original price was: $20.00.$16.00Current price is: $16.00.

- Connection: Male

- Product name: Rotary union for Printing Machinery

- Medium: Steam

- Standard: ANSI

- Color: Customized

- Tolerable temperature: 220℃

- Maximum speed: 100RPM

- Apply pressure: 1.8MPA

-

Sale!

$15.00 Original price was: $15.00.$12.00Current price is: $12.00.

-

Sale!

$10.00 Original price was: $10.00.$9.50Current price is: $9.50.

- Product name: Bearings for Offset Print Heidelberg Printer Machine

- Model: F-217813/ F-222190 /F-229817

- Weight: F-217813: 0.1KG/ F-222190: 0.05KG/ F-229817: 0.015KG

- Using the model: Heidelberg F-217813 SM74 PM74 /F-222190 SM52 PM52 SX52/ F-229817 CD74 XL75 SM102 CD102

- Applicable Industries: Pirnting shops/ factory/ repair shop

- Use: Heidelberg

- Printing Type: Offset printing

-

- Medium: Steam, Hot Oil

- Max Temperature: 260°C

- Max Pressure: 3.5 MPa

- Max Speed: 100 RPM

- Seal Type: Convex Spherical Seal

- Material: Stainless Steel/Carbon Graphite

- Applications: Corrugated Paper Machines